An example of gold extraction from All-mud cyanide -Sint Hel

2020-09-04 09:48Introduction:An example of gold extraction from All-mud cyanide -S i n t H e lena G old Mine , USA The old cyanide plant of Sint Helena Gold Mine was put into operation in 1951. Due to the increase of ore quantity, the serious corrosion of the plant, t

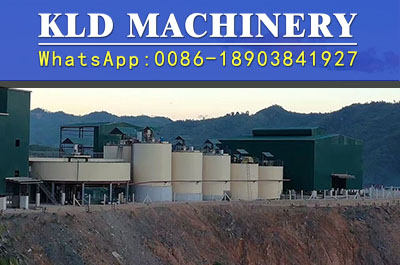

The old cyanide plant of Sint Helena Gold Mine was put into operation in 1951. Due to the increase of ore quantity, the serious corrosion of the plant, the old equipment and the decrease of gold recovery rate, it decided to build a new plant. The new plant was designed to draw on the grinding practices of the old plant since 1956 and the Leslie Gold mine since 1963. The Kinross beneficiation plant, which had reduced production costs and saved labour since 1967, was completed and put into operation in September 1976. The monthly treatment capacity is 300000 tons of ore.

The new plant has no waste rock sorting and crushing operations, ore fragile, ore from the mine directly into the mill or add a small amount of 100 mm steel ball (semi-self-mill). The self-grinding mill and the Krebs (Krebs) cyclone form a closed circuit. The pulp is ground to -200 mesh and sent to 10 flat bottom air mixing tanks for cyanidation. The air hoist circulates in the center of the slurry through the tank, and six high-pressure air nozzles are arranged around the hoist to stir the slurry. To prevent mud from settling down.

The leaching slurry is filtered by vacuum filter, the pregnant solution is clarified by upflow sand filter box, deoxidized by Crowe degassing tower, and the gold mud from gold deposit is replaced by zinc powder after dehydration of horizontal belt filter, and the tunnel kiln is closed for roasting. After calcination and drying, gold mud is sent to large electric arc furnace to shorten melting time, and dust is collected by cloth bag dust collector.